本文由 AIRLAB 授权mooool发表,欢迎转发,禁止以mooool编辑版本转载。

Thanks AIRLAB for authorizing the publication of the project on mooool. Text description provided by AIRLAB.

AIRLAB:AirMesh是世界上第一个由不锈钢3D打印组件制成的建筑结构,它突破了建筑在创新和技术上的轻盈极限,也展示出了新加坡科技大学AirLab最先进的数字化设计和制造技术。

AIRLAB:AirMesh pushes the limits of lightness in Architectural innovation and Building Technologies, becoming the world first architectural structure made of 3D printed components in stainless steel, demonstrating state-of-the-art digital design and manufacturing technologies developed by AirLab at Singapore University of Technology and Design.

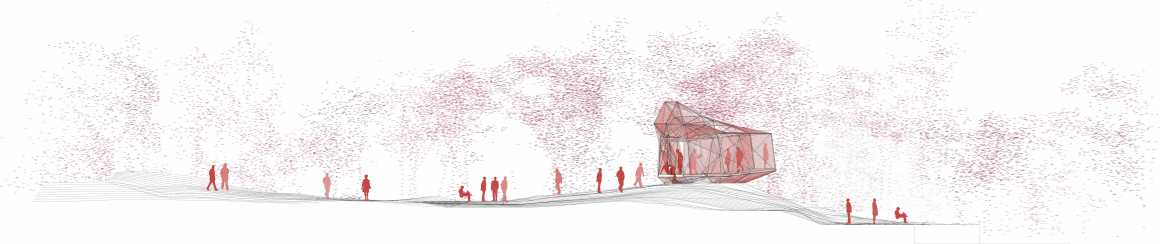

该超轻展馆位于新加坡海湾花园附近,既是一个聚集空间,也是一个轻雕塑艺术。它是新加坡建筑管理局(BCA)及市建局批准的首个遵循欧洲法规而设计的3D打印的临时使用结构,将在花园中一直开放至2020年。

The ultra-lightweight pavilion, located at Gardens by the Bay, is both a gathering space and a light sculpture. The state-of-the-art design follows Eurocode regulations, and is the first 3D Printed structure that has been approved by the Singapore Building Construction Authority (BCA) for temporary occupation in Singapore. The pavilion, also approved by URA (Urban Redevelopment Authority) will still be available to visit in 2020.

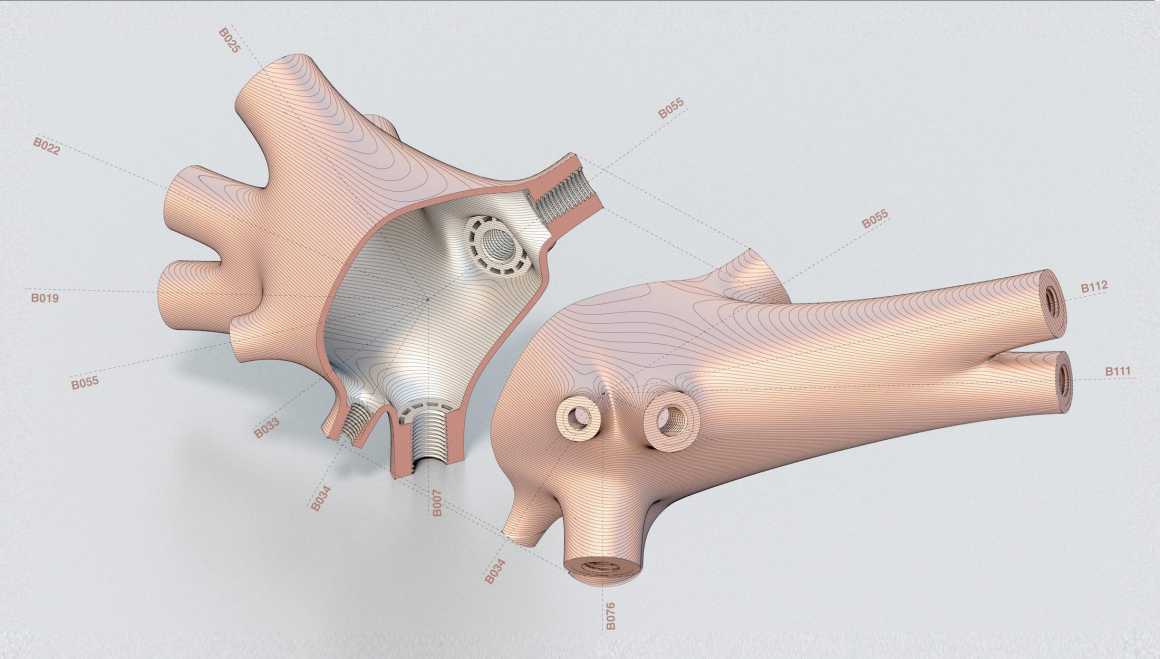

为了减少建设过程中材料的使用,并充分实现建筑设计中的绝对自由形式,AirLab经过四年多的研究,开发了一种全新的建设系统:在不锈钢材料中加入3D打印技术,制造极其复杂的结构优化组件,实现制造过程中的材料零浪费;利用定制的连接系统,将这些组件与标准钢管型材相结合,再使用各种尺寸的六角键将其组装时间缩短到几秒钟。

With the vision of reducing the usage of material in construction, and to fully enable absolute free-form in Architectural design, an entirely new constructive system by AirLab has been developed over more than four years of research. Using Additive Manufacturing (3D Printing) in Stainless Steel, extremely complex structurally optimised components can be fabricated achieving zero wastage of material in the fabrication process; those components are combined with standard steel tubular profiles thanks to a bespoke connection system which reduces the assembly time to a few seconds using hex keys of different size.

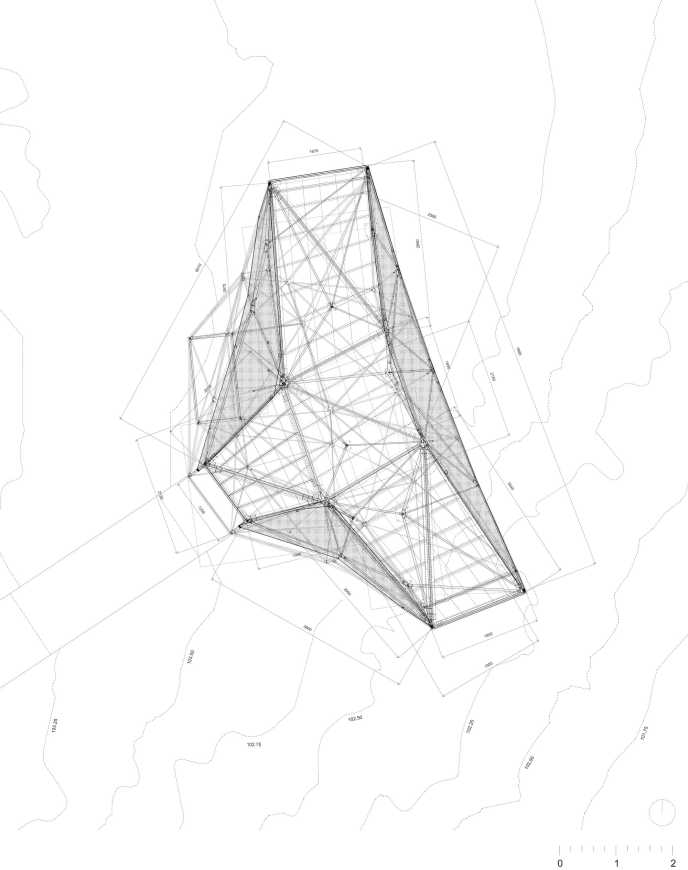

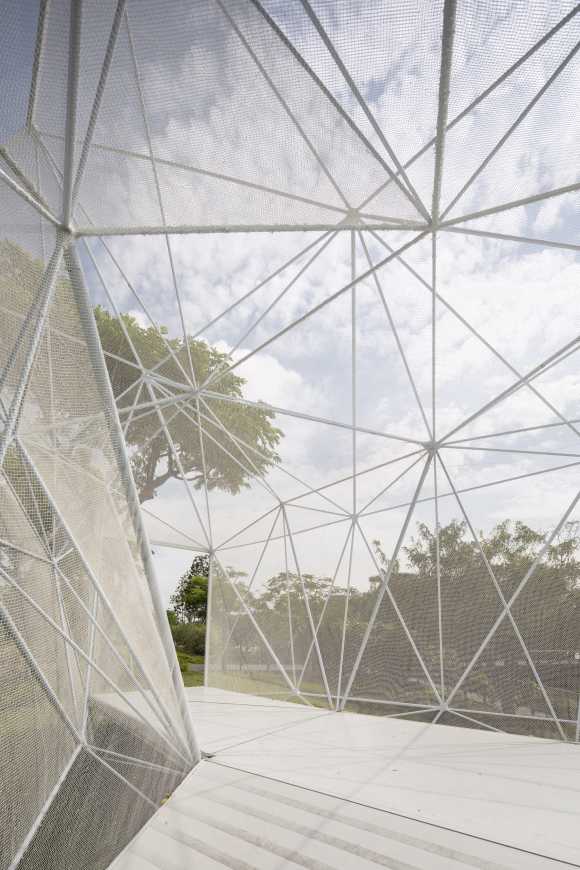

若你站在不同角度,会看到不同形状的AirMesh:它由四个面向周围景观亮点(蜻蜓桥、银色花园、Marina海湾沙滩和展馆入口)的取景框架构成,四个矩形框架组合在一起构成了展馆空间,其多面式的渐变颜色照明也使它看起来好似一个传统的中国灯笼。

The pragmatic form of AirMesh is defined by the views’ directions. The volume is defined by four vectors oriented towards highlights in the surrounding landscape: the dragonfly bridge, the silver garden, the Marina Bay Sands, and the pavilion entrance. The space is generated by four rectangular view frames, and its faceted form reinterprets a traditional Chinese lantern, lighting up in subtile color gradients.

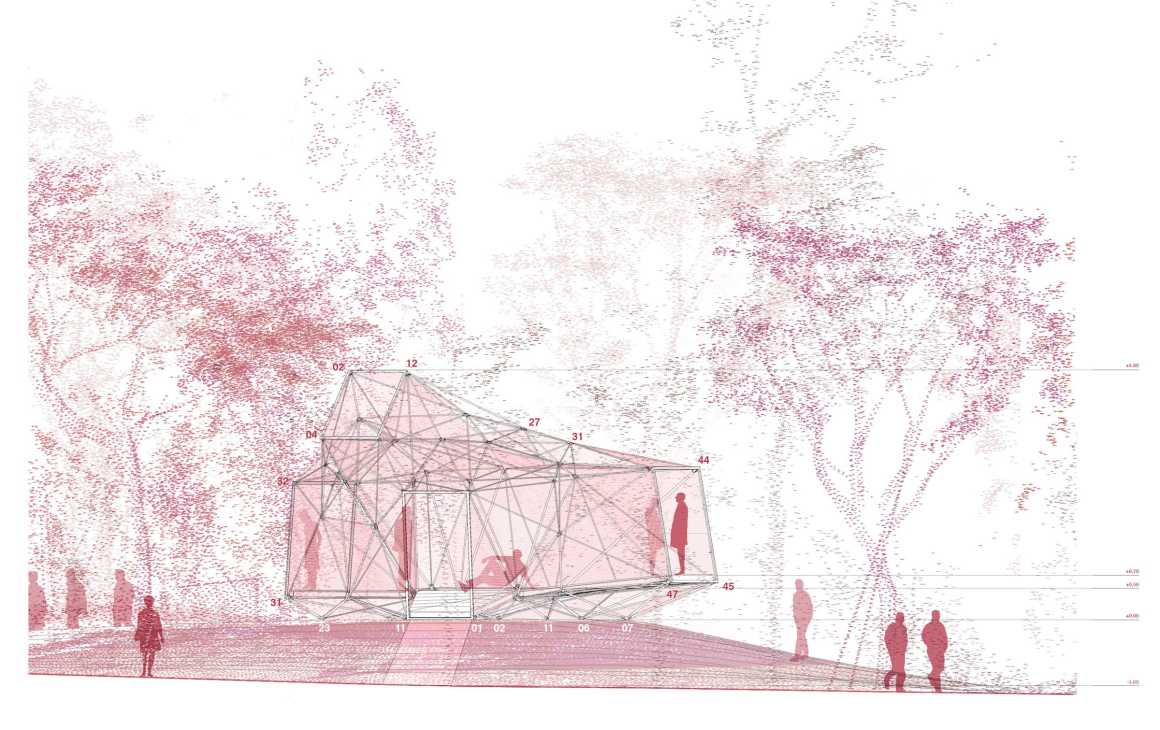

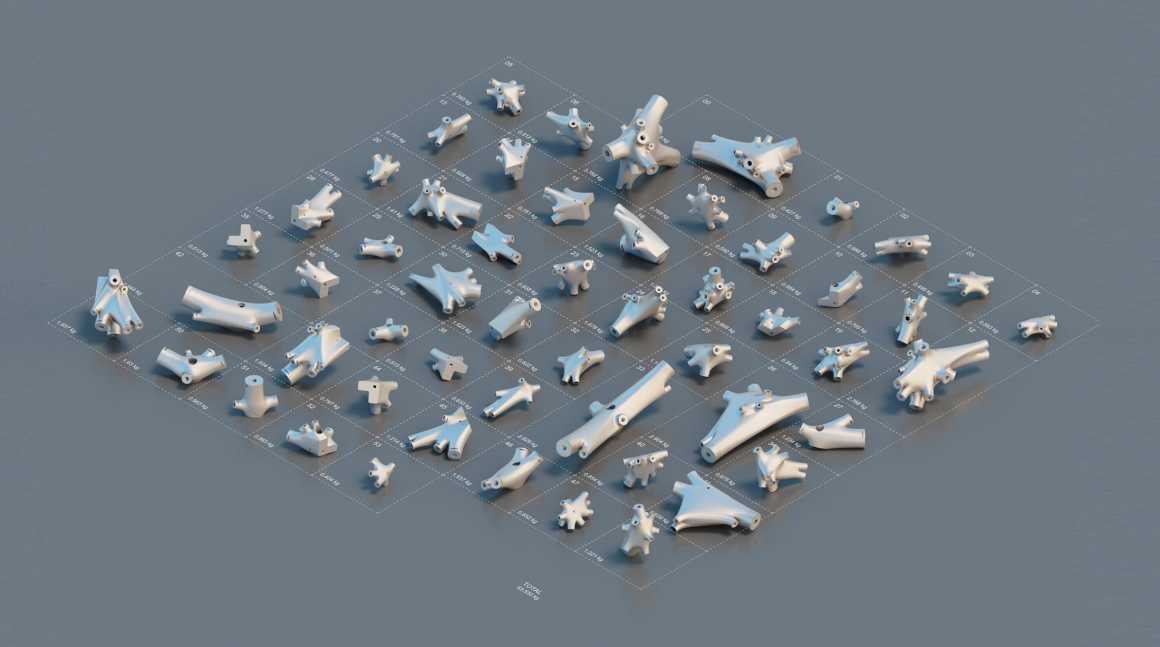

该展馆由216根不同长度和截面的钢筋和54个独特的、由钢和青铜合金制成连接节点组成,为了创建最有效的结构设计,设计团队使用自定义参数化工具,优化了框架的拓扑结构、杆的截面和节点的几何形状,因此,该结构在原本机械性的地方呈现出了最佳的结构和材料分布。

The structure was designed using a custom parametric tool that optimizes the topology of the frame, the section of the bars and the geometry of the node with the objective of creating the most efficient structural design. As a result, the structure presents the optimal configuration and distribution of material where mechanically needed. The pavilion consists of 216 bars of different lengths and sections, and 54 unique nodal joints printed in a steel and bronze alloy.

基于以上元件连接的重大技术创新应用,能够3D打印节点内部的螺纹,便于用隐藏在杆内的螺栓进行装配,组装整个展馆只需要不同直径的六角键,该结构的组装仅用五个人花了两天时间完成,其小于1毫米的系统允许公差,以及各组件的完美配合,使得该不锈钢结构的建造速度和性能都创下了一个历史新高。

The assembly of the structure took only two days by five people, as a result of big technological innovation applied to the connection of the elements, being able to 3D print the threads inside the nodes to facilitate the assemblage with bolts concealed in the bars. Only hex keys of different diameter were needed to assemble the entire pavilion. The system allows for tolerances of less than a milli metre and perfect fit of components, taking construction in stainless-steel to a next level of rapidity and performance.

虽然展馆结构外观精致,却有大于其自身重量(700公斤)16倍的承重能力——超过11吨。

The structure has a weight of 700 kg, and despite its delicate and fine appearance, is able to withstand loads 16 times its weight – more than 11 tones.

通常,这样的一个空间框架系统都由一种规则模式重复组成,这主要是因为人们很难用有限的几个标准节点来解析复杂的几何图形,但现在的3D打印不需要使用标准零件和重复图案导致经济效益降低,所以为了这种框架构筑的设计有更大的自由设计空间,我们使用了新的工具和创新技术来建造Airmesh。

Typically, current space frames systems consists of a repetition of a regular pattern, primarily due to the impossibility of resolving complex geometries with a limited number of standard nodes. As 3D-printing eliminates the incentive of using standard parts, the economic benefits of using a repetitive pattern is reduced. To design space frames with this greater design freedom, new tools, technology and innovation were required to materialise Airmesh.

如果说数字化设计为无限的几何自由、大规模定制和优化、装饰性、多功能建筑结构打开了创造力的大门,那么,3D打印技术就是帮助人们将狂野的设计愿景变为现实,但由于目前规模、时间和成本的限制,这一目标暂未能完全实现。Airmesh项目中所用的方法不是3D打印整个结构,而是将3D打印的组件与标准元素无缝地结合在一起,否则会导致非常高的生产成本,现在它已经在快速组装和一定的经济范围内,为自由形式设计铺平了道路。

Digital design opens creativity to nearly endless geometric freedom, mass-customization, and optimized, ornamental, multifunctional architectural structures. In tandem, 3D Printing served as a promise to materialize wild design visions into built reality; yet an unfulfilled one due to size, time and cost constraints. AIRMESH approach, rather than 3D printing the entire structure which would result in very high costs of production, combines 3D printed components with standard elements in a seamless way. It sets path for full free-form designs, with a rapid assembly and in a more affordable range.

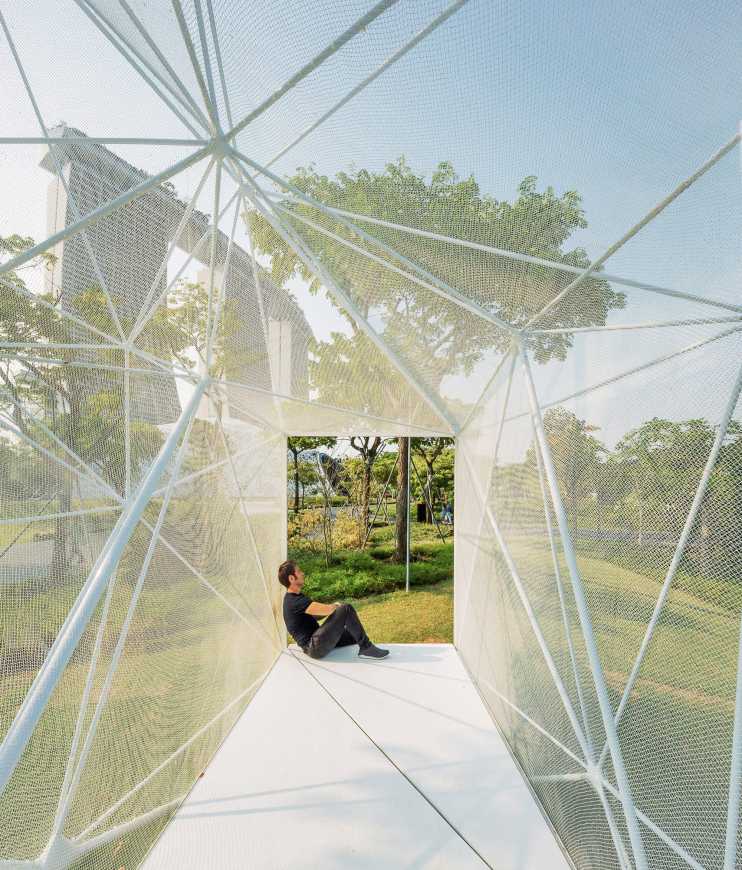

与钢筋无缝融合的节点形式,赋予了结构一种连续性和流动感。展馆的双层透气表层是一个紧绷在结构上的多孔渔网,其透明性在帮助微风透入的同时、也证明了这种清晰的结构可捕获各种颜色的光,将未经任何过滤的外部风景框入立面开口作为展馆内部的观赏主景。

The form of the nodes blends seamlessly with the bars, giving the whole a sense of continuity and structural fluidity across its components. The two-layered breathable skin of the pavilion is a porous fishing net tensed towards the structure. Its transparency allows the breeze to pass and the structure to be seen yet evidences the form and captures the RGB light. The view frames serve as openings for the envelope, where the primary views are presented unfiltered.

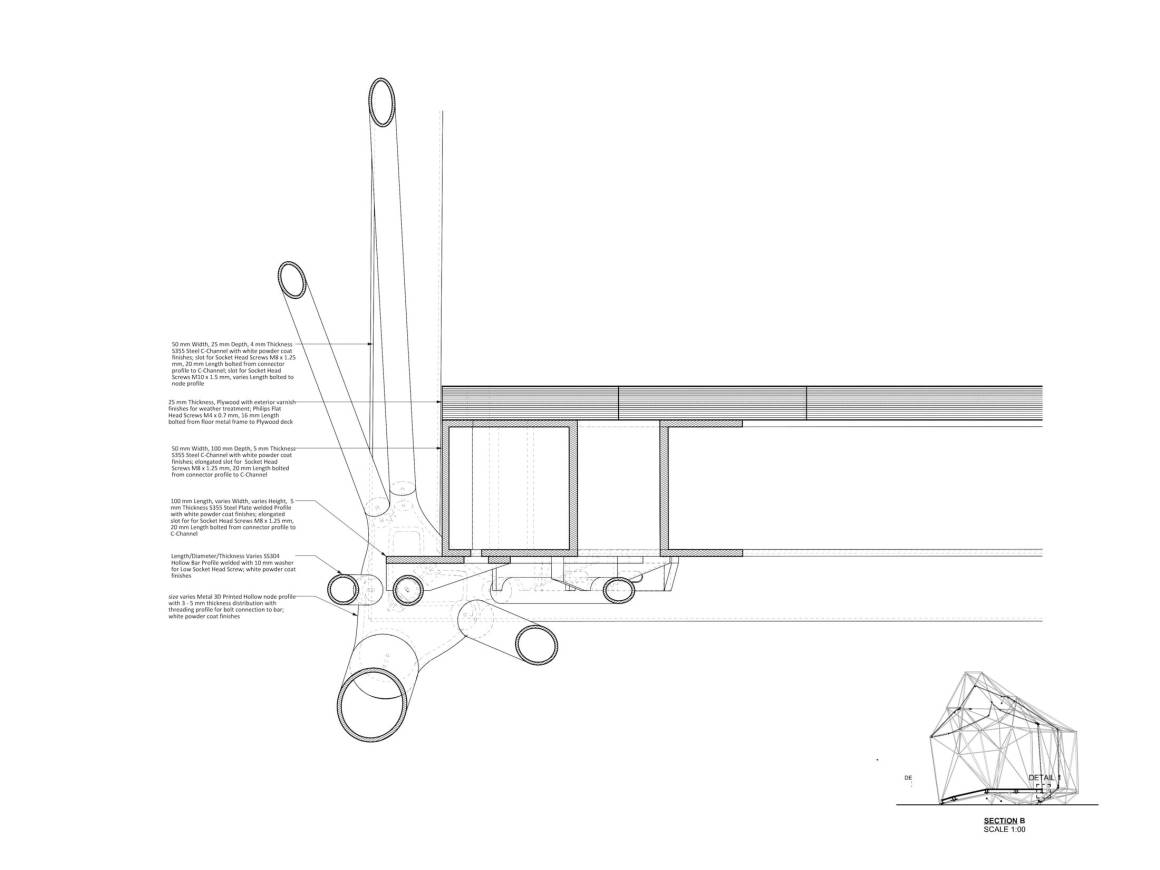

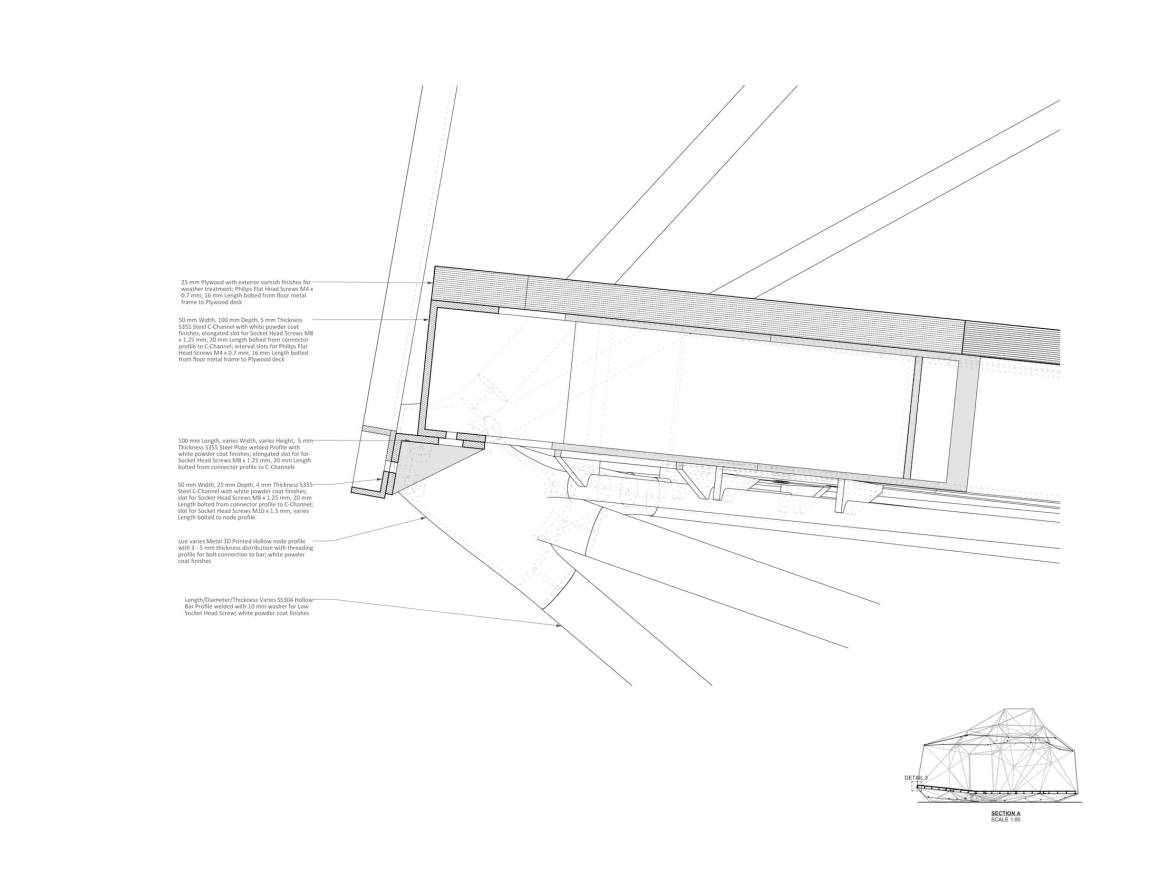

▼展馆结构细节 Detail

▼场地平面图 Site Plan

▼展馆立面图 Elevations

▼展馆平面图 Floor Plan

▼展馆结构细节图 Details

▼展馆结构连接构件模型图 The hex keys

设计:AIRLAB(建筑智能研究实验室)@SUTD

项目负责人:Carlos Banon and Felix Raspall

首席研究员:Anna Toh Hui Ping

研究团队:David Rosen, Vahid Hassani, Jenn Chong, Sourabh Maheshwary, Sihan Wang, Liu Chi, Huang Kunsheng, Luo Qihuan, Aurelia Chan, Cheong Yilei

顾问:TCP Engineers, PTL Consultants, WoodFix

面积:28.75平方米(框架边界8.2 x 5.6 x 5.6)

体积:88.5立方米

项目地点:新加坡

海湾花园滨水亭

项目时间:2017年8月开始

竣工:2019年8月

Designed by AIRLAB (Architecture Intelligence Research Lab) @SUTD

Project Lead: Carlos Banon and Felix Raspall

Lead Researcher : Anna Toh Hui Ping

Research Team: David Rosen, Vahid Hassani, Jenn Chong, Sourabh Maheshwary, Sihan Wang, Liu Chi, Huang Kunsheng, Luo Qihuan, Aurelia Chan, Cheong Yilei

Consultants: TCP Engineers, PTL Consultants, WoodFix

Surface: 28.75 sqm (bounding box 8.2m x 5.6m x 4.8m)

Volume: 88.5 m3

Location: Bayfront Pavilion, Gardens by the Bay. Singapore

Project duration: Beginning in August, 2017

Completion in August 2019

更多 Read more about: AIRLAB

0 Comments