本文由 MC A 建筑事务所 授权mooool发表,欢迎转发,禁止以mooool编辑版本转载。

Thanks Mario Cucinella Architects for authorizing the publication of the project on mooool. Text description provided by Mario Cucinella Architects.

MC A:“TECLA是通向未来的钥匙,将开启一个全新的时代:利用现代科技转化传统材料以适应社会的可持续发展。建筑的外形是技术研究与材料探索的共同成果,而非仅仅是美学上的尝试。它的形式是审美、材料、功能与技术的结合,充分展现了对环境和生活的同理心。” ——Mario Cucinella,MC A建筑事务所创始人

MC A: “We like to think that TECLA is the beginning of a new story. It would be truly extraordinary to shape the future by transforming this ancient material with the technologies we have available today. The aesthetics of this house are the result of a technical and material effort; it was not an aesthetic approach only. It is an honest form, a sincere form. ” Mario Cucinella – Founder and Creative Director of Mario Cucinella Architects.

MC A建筑事务所(Mario Cucinella Architects)与WASP合作完成的TECLA项目,是世界上首个完全由生土材料通过3D打印制作而成的生态住宅。项目极具创造力和先锋性,展现了对本土建筑实践、气候和生物气候原理研究的成果,是结合了天然本土材料的使用经验以及对最先进的3D打印技术应用的集大成作品。

The TECLA project completed by (Mario Cucinella Architects in cooperation with WASP is the world’s first eco-sustainable house 3D printed from raw earth. The project is extremely creative and pioneering, showing the results of research on local architectural practices, climate and bioclimatic principles. It is a masterpiece that combines the experience of using natural local materials and the application of the most advanced 3D printing technology.

▼起居室 Living room

设计背景 Design Background

无论是在大城市的边缘地带,还是在大量移民及其后代涌入的地区,抑或是自然灾害引发危机的地方,应对这些地方的气候并解决住房需求问题,TECLA应运而生。满足了Km0 (就地取材,材料无需运输,不产生废弃物)可持续住宅的的需求。

Whether it is on the fringes of big cities, in areas where a large number of immigrants, or in places where natural disasters trigger crises, respond to the climate in these places and solve the housing needs problems, TECLA came into being. It meets the needs of Km0 (on-site materials, no need to transport materials, and no waste) for sustainable housing.

▼入口处夜景 Night view at the entrance

设计概念 Design Concept

项目的名字TECLA以隐喻的形式映射了卡尔维诺的“看不见的城市”之一——持续建造中的城市,通过将古代住宅的材料经验和气候智慧与二十一世纪的技术产物结合在一起,连接过去与未来,重新思考建筑。

与传统建筑技术相比,它具有耗时少、节省原材料,减少建设过程中废弃物排放的优点。

Metaphorically inspired by one of Italo Calvino’s ‘invisible cities’ – the city in continuous construction – the name TECLA evokes the strong link between past and future by combining the matter and spirit of timeless ancient homes with the world of 21st-century technological production.

Compared with traditional construction technology, it has the advantages of less time-consuming, saving raw materials, and reducing waste discharge during the construction process.

▼夜景立面 Night view facade

▼主入口 Main entrance

TECLA

TECLA是一个创新的圆形经济住房模型,将传统建造实践、生物气候原理和当地的天然材料整合在一起。这是一个接近零碳排放的项目,完全由当地生土材料制成,其外形和选材减少了材料的剩余和浪费,使TECLA成为了低碳住房的一个先锋示例。

TECLA is an innovative circular housing model that brings together research on vernacular construction practices, the study of bioclimatic principles and the use of natural and local materials. It is a nearly zero-emission project: its casing and the use of an entirely local material allows for the reduction of waste and scraps. This and the use of raw earth make TECLA a pioneering example of low-carbon housing.

功能与形态 Function and form

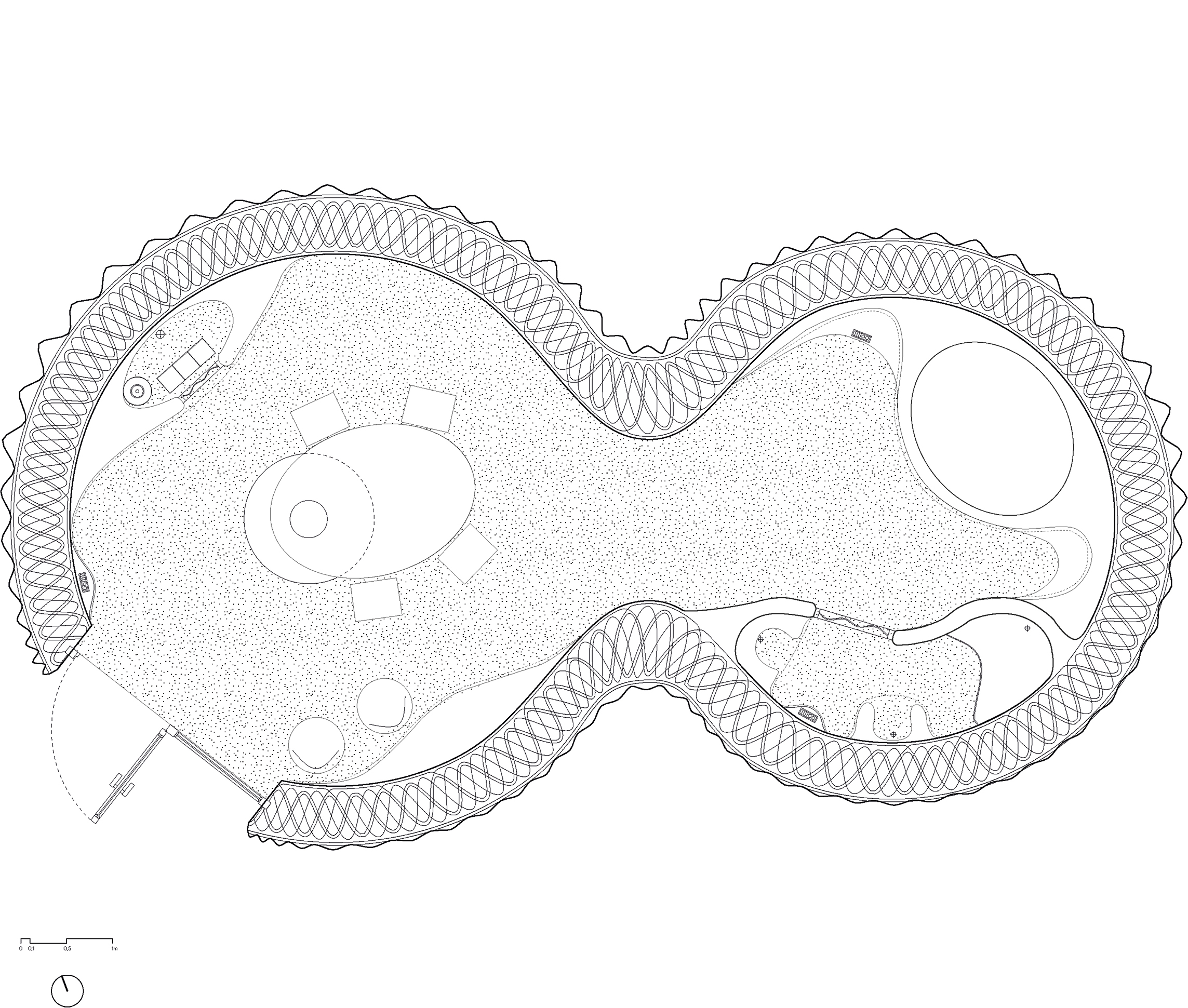

项目的建筑面积约60平方米,包含一个带厨房的起居空间,以及一个带卫生间的卧室。家具部分也由生土打印而成,与建筑结构融为一体;部分采用可循环利用的绿色设计,反映出住宅背后的生态理念。

With an area of about 60 square meters, it comprises a living zone with a kitchen and a night zone which includes services. The furnishings – partly printed in local earth and integrated into the raw-earth structure, and partly designed to be recycled or reused – reflect the philosophy of a circular house model.

▼卧室顶部的圆形天窗 A circular skylight at the top of the bedroom

TECLA由两个连续的元素组成,两条弯曲的正弦曲线向上生成建筑,顶部留下两个圆形天窗,为室内投入天光。从几何形态到外部屋脊,建筑非典型的形状满足了3D打印外壳以及封顶后的结构平衡需求,将有机而又连贯的设计活灵活现地呈现在人们面前。

TECLA is a composition of two continuous elements that through a sinuous and uninterrupted sine curve culminate in two circular skylights that convey the ‘zenith light’. The atypical shape, from the geometry to the external ridges, has enabled the structural balance of the construction – both during the 3D printing phase of the envelope and once the covering is completed – giving life to an organic and visually coherent design.

▼圆形天窗为室内投入天光 The circular skylight that convey the ‘zenith light’

结构优化 Structure optimization

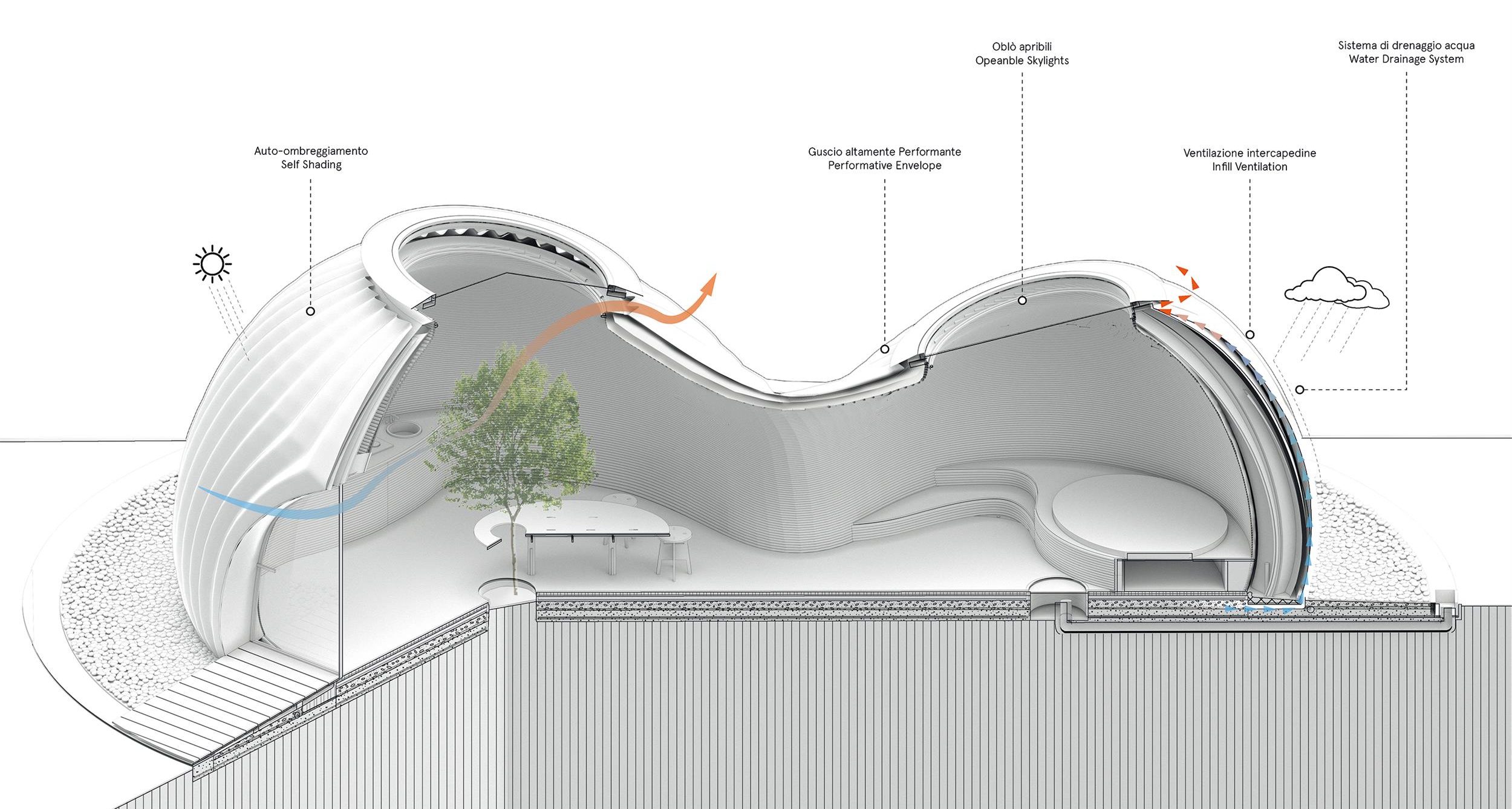

与传统建筑技术相比,3D打印技术的创新之处主要体现在建筑形态的极度灵活性上。结构设计从黄蜂的蜂巢结构中汲取灵感,比任何其他形态的承受力更强,且材料消耗较少。同时具有优越的通风和保温性能。

Compared with traditional building technology, the innovation of 3D printing technology is mainly reflected in the extreme flexibility of the building form. The structural design draws inspiration from the honeycomb structure of the wasp, which is stronger than any other form and consumes less material. At the same time, it has excellent ventilation and heat preservation performance.

▼轴侧节能分析 Energy-saving analysis

▼室外墙面 Outdoor wall

对于内部结构的优化,需要考虑以下三个参数:通风(建筑立面最外层)、隔断(填充层,使用废弃再利用的稻壳)和热质量(随着内部空间“骨骼”结构的增加而增加)。在无数排列组合中每一种气候类型都可以找到与之对应的最佳配置。例如,对于非常潮湿的气候,能够存储多余湿度的热质量是关键,需加宽正弦曲线的弯曲弧度,加大通风层的开口。同理,在寒冷的气候条件下,隔热层是应对的关键,因此需限制建筑表皮层与外界冷空气的接触。

优化矩阵图像的结果显示,从本地材料和节能概念入手,内部空间能够适应环境,确保最高水平的内部舒适度。

For the optimization of the internal structure, the following three parameters need to be considered: ventilation (outermost layer of the building facade), partition (filling layer, using discarded and reused rice husks) and thermal quality (as the internal space “skeleton” structure increases And increase). In countless permutations and combinations, each climate type can find the best configuration corresponding to it. For example, for a very humid climate, the thermal mass that can store excess humidity is the key. It is necessary to widen the curvature of the sinusoidal curve and increase the opening of the ventilation layer. In the same way, in cold weather conditions, the insulation layer is the key to coping with it, so it is necessary to limit the contact between the building skin layer and the outside cold air.

The result of optimizing the matrix image shows that starting from local materials and energy-saving concepts, the internal space can adapt to the environment to ensure the highest level of internal comfort.

▼室内墙面 Interior wall

3D打印 Printing

WASP公司的研究专注于Km0生土3D打印,形成了名为Crane WASP的创新3D打印技术。这是世界中首个模块化多层打印技术,可以合作性地完成建造工作。TECLA同时使用两条打印机械臂,其动作经过软件优化,避免了碰撞的发生,保证操作流畅。每个打印单元可以打印的范围为50平米,能够在短短几天中建造出独立的住宅。

TECLA的建造花费了200小时,使用了7000条机器代码,共包含350个12毫米的分层,展开长度为150千米,消耗自然材料60立方米,平均能耗6千瓦。

The technological research of WASP, specialised in Km0 3D printing from raw earth, has led to an innovative 3D printing technology called Crane WASP, the first in the world to be modular and multilevel, designed to build construction works collaboratively. TECLA uses two synchronised printer arms simultaneously, thanks to software capable of optimising movements, avoiding collisions and ensuring streamlined operation. Each printer unit has a printing area of 50 square meters which therefore makes it possible to build independent housing modules in a few days.

TECLA can be delivered with 200 hours of printing, 7000 machine codes (G-code), 350 12 mm layers, 150 km of extrusion, 60 cubic meters of natural materials for an average consumption of less than 6 kW.

社区规划 Community planning

位于意大利马萨伦巴达的TECLA项目并不只是一个孤立的生态住宅,它所提倡的是对社区的总体规划。旨在创建可实现独立自产,自主实现水资源及其他能源的分配、循环、对废弃物进行回收利用的小型智能生态社区。

The TECLA project located in Massa Lumbarda, Italy. It is not just an isolated ecological house, it advocates a masterplan for the community. The aim is to create a small smart ecological community that can realize independent self-production, distribution and recycling of water resources and other energy sources, and recycling of waste.

▼平面图 Plan

▼剖面图 Section

设计团队:MC A建筑事务所

团队成员: Mario Cucinella, Irene Giglio , Augusto Barichello

可持续性研究团队:SOS – School of Sustainability (意大利可持续发展学院)

团队成员:Lorenzo Porcelli, Stefano Rosso, Lori Zillante

3D打印技术项目合作团队:WASP

团队成员:Massimo Moretti, lapo Naldoni, Alberto Chiusoli, Francesco De Fabritis, Massimo Visonà

项目支持:意大利拉文那 Massa Lombarda政府

门窗设计:Capoferri Serramenti

机电设计:Cefla

景观设计:Frassinago

木材配件:Imola Legno

灯光设计:Lucifero’s

填充材料优化设计:Mapei

结构设计:Milan Ingegneria

家具设计:Officine Tamborrino

施工监理: WASP

Design Team: MC A

Team Members: Mario Cucinella, Irene Giglio , Augusto Barichello

Sustainability Research Team: SOS – School of Sustainability

Team Members: Lorenzo Porcelli, Stefano Rosso, Lori Zillante

3D Printing Technology Project Cooperation Team: WASP

Team Members: Massimo Moretti, lapo Naldoni, Alberto Chiusoli, Francesco De Fabritis, Massimo Visonà

Project Support: Levana Massa Lombarda Government

Door and Window Design: Capoferri Serramenti

M&E Design: Cefla

Landscape Design: Frassinago

Wood Accessories: Imola Legno

Lighting Design: Lucifero’s

Optimization Design of Filling Materials: Mapei

Structural Design: Milan Ingegneria

Furniture Design: Officine Tamborrino

Construction Supervisor: WASP

更多read more about: MC A 建筑事务所

0 Comments